We are currently running 5 cabs on battery along with the 7 original cabs. As a side

note the S- t require direction information. Of course with

the Chubb system this is accomplished with a simple program change!

t require direction information. Of course with

the Chubb system this is accomplished with a simple program change!

I believe that battery operated locomotives coupled with DCC will in the future be the system of choice as it does not depend on track contact for power or communications.

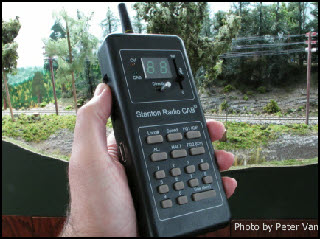

In 2012 while at a railroad meet I was introduced to S-

I purchased one cab and the necessary components and installed them in the non motored “B” unit pictured to the left. This setup powers two trains from Milpitas to Salt Lake, both out and back for a total of four trips over basically the entire railroad. We found we would loose power on the forth trip out of Salt Lake. I then installed a short power track at each end so the unit could recharge between runs. This solved that problem!

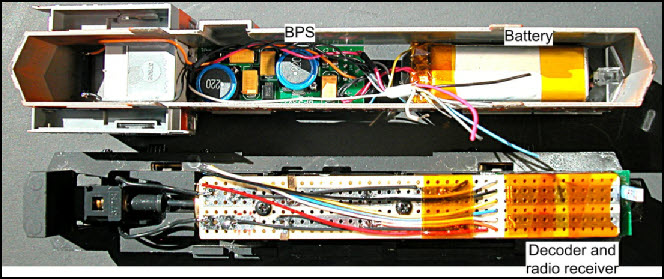

Stalling has always been a problem in the yards, so this was the next project. There was no way the components would fit in a switching locomotive so I went to a solution the railroads used when additional power was needed. This was referred to as a cow and calf. On my railroad the calf is non powered and contains the battery, the battery maintenance components and a DCC decoder that allows the throttle to communicate with the locomotive.

The Cow and Calf yard switcher.

After a time of experimenting and some changes to the system we then installed the units in GP35 and GP7 road engines. The GP35 works the Reno yard and makes a run to Oakland and back. One advantage with the system is that you can charge the battery with track power. As a safety backup I leave track power on in both the Stockton and Reno yards so the battery is getting a boost constantly. The GP7 is assigned to the Fruit Express out of Salt Lake running to Turlock. The power is then used by the Valley Can that serves Turlock, Stockton and Fruitvale. Then returns to Turlock where the power is then used to return the Fruit Express to Salt Lake.

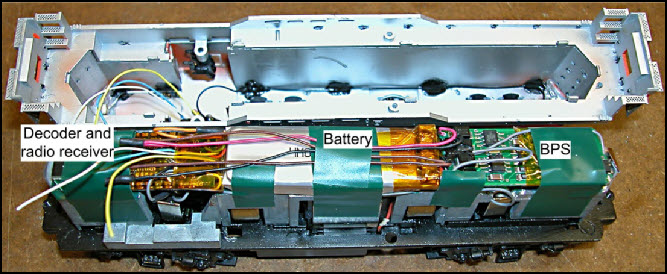

These are photographs of the GP35 installation.

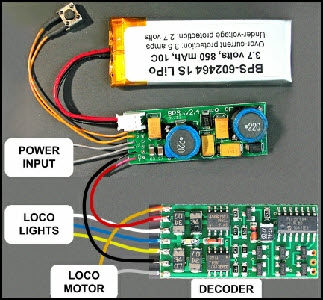

Even during the short time I have been using the system we have seen improvements in the battery's. These are 3.7 volt battery's. The battery maintenance board handles the recharging and kicks the voltage up to the level needed for reliable operation.

Further information on the S-

GP35 Installation

GP7 Installation